The Anatomy of Footwear Cushioning

Many layers contribute to overall footwear comfort, and we’re taking apart a shoe to go inside each layer and how it helps with everything from cushioning to rebound.

Setting out to achieve optimal insole comfort for a majority of footwear customers was never a small feat, which is why it’s taken us years to perfect our ProvenComfort™ system of tools and analysis that can deliver a level of comfort for our insoles that work for most wearers.

Our mission in delivering proven comfort isn’t just to elevate insole quality for footwear brands, but to help eliminate the need for consumers to seek aftermarket insoles as an additional purchase. Achieving those results means developing an insole that truly fits – right out of the box – for a majority of customers.

In any industry, proof of efficacy is paramount to winning consumer trust and building equity for your brand and product. Everything from customer reviews to certifications from top regulatory organizations helps prove that what you’re producing is effective and legitimate.

Plus, today’s consumers see right through attempts to cut corners or falsely promote results. With so many products on the market to choose from, consumers are inundated with buzzwords and marketing-speak that begin to mean, well, nothing after a while.

In the insole industry for one, the promise of “comfort” is touted so often that it’s taken on a relatively ambiguous quality where only the individual wearing the insole can decide what’s truly comfortable to them. What we set out to do at INSITE was design insoles using tools and processes that would get our insoles as close as possible to that optimal feeling of comfort.

Our approach seeks to quantify comfort through psychological and physical tests that combine machine analysis with human testers for a full-spectrum assessment of what optimal comfort looks and feels like.

How do we quantify comfort? Through data analysis of course! Everything always comes back to data – it’s the only way to know what works, and what doesn’t, and accurately analyze direct responses and reactions to different factors.

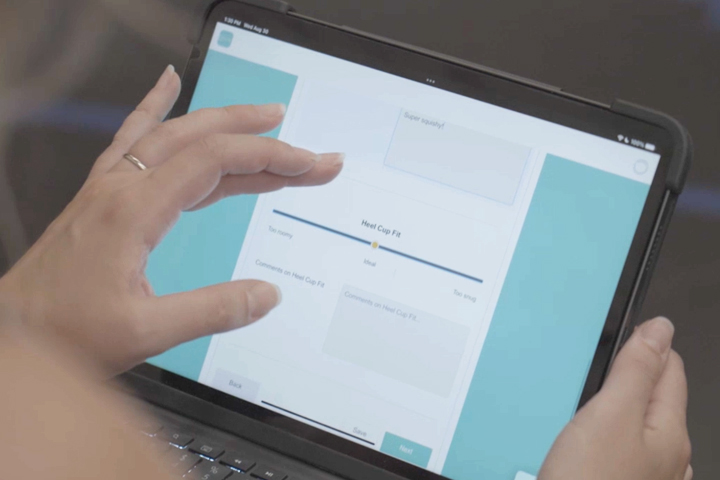

Our ProvenComfort™ process is a series of third-party validated tests that help us benchmark specific comfort metrics – so that brands have the data to make better product decisions. We capture individual perceptions of what comfort really means, conducting in-depth psychometric surveys that help quantify the fit, placement, and cushioning of the insole during different movements and activities. By examining specific comfort variables, we can take into account both individual experiences with shoe and insole performance, as well as overall trends in comfort perception.

Here’s a breakdown of what these tests look like:

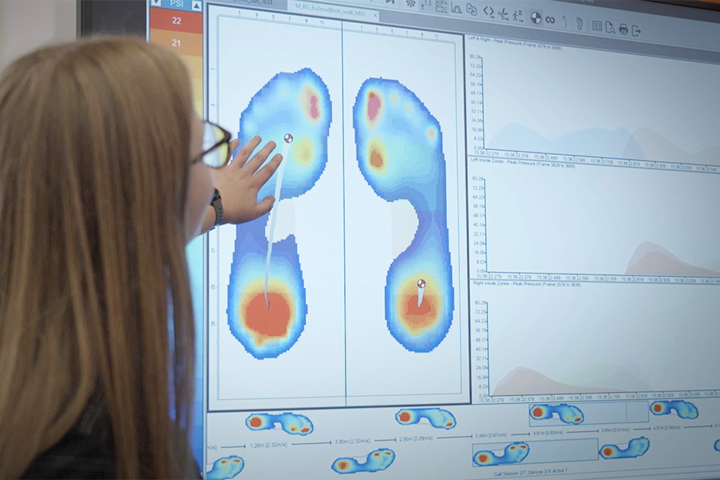

Using high-fidelity wireless insole sensors, we visually map underfoot pressure in real-time during activity. This allows us to gain data and analysis on plantar pressure, the foot’s center of pressure, and gait – helping us identify pressure “hot spots” and reduce discomfort through insole design.

Using a computer-controlled test that simulates heel and forefoot impact, we measure the compression, shock absorption, and rebound of the shoe’s cushioning system to understand the level of impact created by the foot during certain activities. This testing allows us to see how that impact is absorbed by an insole and the effect of footwear on a wearer’s foot over time.

In addition to our core ProvenComfort testing methods, INSITE also offers advanced biomechanics testing – providing even more detailed comfort metrics for high-performance footwear applications. This biomechanics testing includes multiple components:

Using the data from these valuable tests informs our insole shape, materials, and design, with the final product being an insole that fits your footwear and fits your customers.

Providing a comfortable insole right out of the box carries several benefits for your brand – you can offer that vital and sought-after validation of your comfort and performance claims, and benchmark your product’s performance against your competitors.

Plus, when you have data behind the comfort you’re offering, it’s easier to evolve your products and make updates that move them forward.

Leveraging leading biomechanics science to inform your products is an excellent innovation story that is attractive to customers and helps increase product confidence through valuable data points.

The only way to know how our insole comfort analysis tools really work is to see the “proof in the pudding” for yourself.

Ready to learn more? Let us send you a custom sample, which we can produce in as little as 14 days based on your midsole or last. Your insole sample undergoes industry-standard performance, safety, and bio-content testing before we send it out to you. This customized sample gives you insight into the efficacy of our ProvenComfort process and how we infuse it into every insole – so you can infuse it into your footwear.

Many layers contribute to overall footwear comfort, and we’re taking apart a shoe to go inside each layer and how it helps with everything from cushioning to rebound.

Discover the three INSITE foam insoles that each satisfy the specific needs brands have for every type of footwear design.

What’s the difference between bio-based foams and recycled foams, and how do each measure up as sustainable insole materials?