Make a Smaller Footprint with Sustainable Insoles

Sustainability at the Source

We believe in delivering the ultimate in insole comfort, performance, and support – while also providing sustainable insoles that both footwear brands and customers can feel good about. Our commitment to sustainability doesn’t just include using plant-based materials – it starts right at the source.

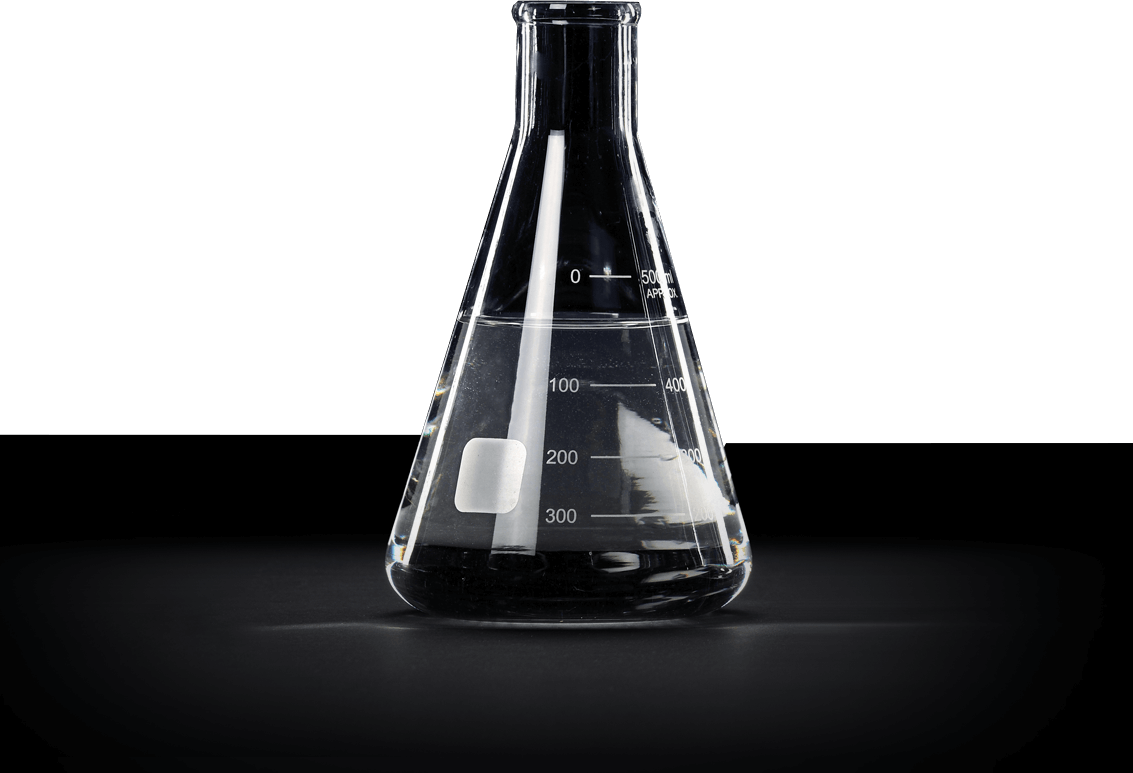

Sustainably Sourced Propanediol

Our proprietary PU foams are made with up to 60% Susterra® propanediol, made from U.S. industrial field corn. Susterra is partnered with the Truterra® program, supporting regenerative practices like no-till farming, crop rotation, and reduced fertilizer and pesticide use.

Susterra Bio-propanediol

Susterra uses the dent corn to create Susterra bio-propanediol, which replaces some of the main petrochemical ingredients in traditional polyurethane, saving carbon emissions and non-renewable energy use. This remarkable compound can also enhance physical properties for better comfort and performance.

The Susterra Difference

Using Susterra propanediol over petrol-based BDO significantly reduces GHG emissions and non-renewable energy use. It can also enhances PU foams with better flexibility, resilience, and durability.

Benefits of Bio-Propanediol

*Based on a peer-reviewed 2024 life cycle assessment, comparing cradle-to-gate production of 100% Susterra bio-propanediol to petroleum-based BDO.

%

Greenhouse

Gas*

%

Non-Renewable

Energy*

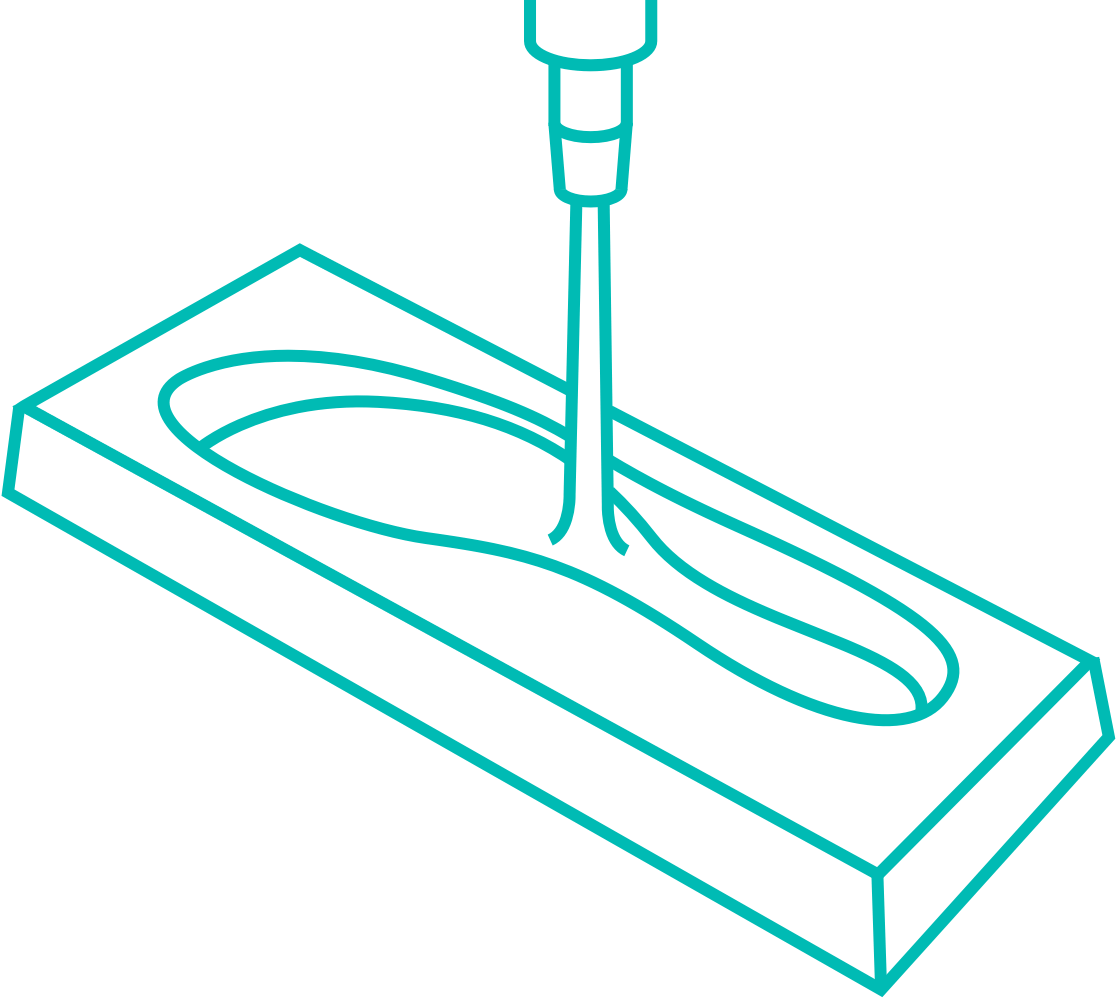

Less Material Waste With Poured PU

INSITE insoles using Levation PU foams are poured or injected into molds, rather than being die-cut from PU sheets. The result is a reduction or elimination of industrial scraps, reducing material waste and increasing manufacturing efficiency.