Performance, Support, & Comfort Insoles That Just Fit

An Exceptional Footwear Experience – Right Out of the Box

INSITE® Insoles are designed to provide comfort, performance, and support – for every shoe and everyone. We use the science of biomechanics to develop insoles that put many of the benefits of a custom orthotic directly into your favorite brand of footwear – so a better experience begins right out of the box.

Skip the Replacement Insole

Brands that partner with INSITE Insoles have built-in comfort, performance, and support in every shoe, so no more hunting for replacement insoles to achieve a better fit. Our insoles are designed to accommodate every activity and body type, from athletes looking to perform their best to workers who need to stay comfortable for long days on the job.

Built on the Science of Foot Health

Get more out of your footwear than just a shoe that fits. INSITE® insoles are designed using industry-leading biomechanics testing and data, helping footwear brands deliver the most comfort, performance, and support possible – right out of the box.

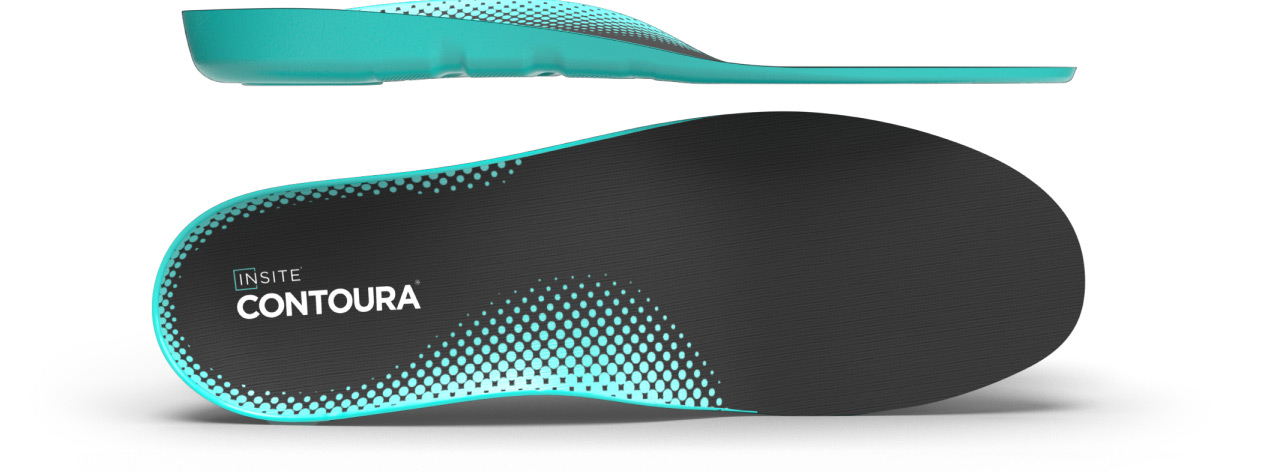

Our patented Contoura® insole shape is designed and approved by podiatrists based on 120,000 3D foot scans, providing you with a custom orthotic feel.

Insole Foams That Go a Step Further

Our innovative insole materials and foam technologies are engineered to support our mission of comfort, performance and support while providing unique sustainability benefits. Using plant-based compounds, planet-friendly manufacturing methods, and responsible materials sourcing, our foams are helping reduce carbon emissions and non-renewable energy use while providing exceptional experiences.